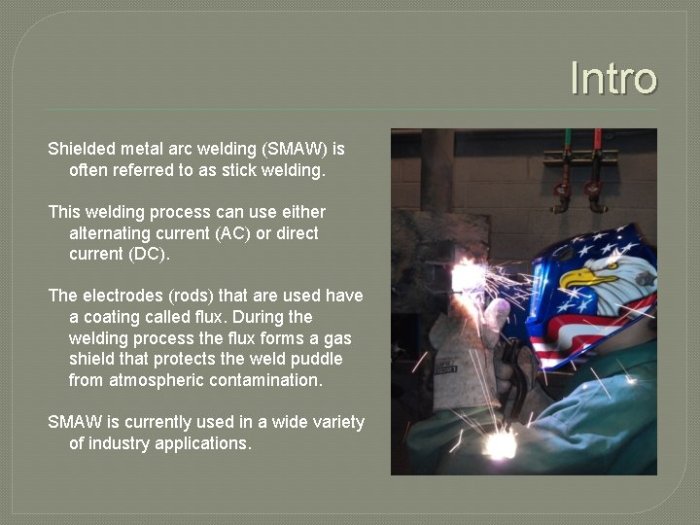

Smaw is often referred to as – SMAW, often referred to as Shielded Metal Arc Welding, is a widely used welding technique that offers versatility and reliability in various industrial applications. This in-depth exploration of SMAW delves into its process, equipment, advantages, and safety considerations, providing a comprehensive understanding of this essential welding method.

SMAW employs a consumable electrode covered with a flux coating, which creates a protective shield of gas around the weld pool, preventing contamination and ensuring weld quality. The process is known for its simplicity, making it accessible to both novice and experienced welders.

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW), also known as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to create an electric arc between the electrode and the workpiece. The flux melts and forms a protective layer of slag over the weld pool, protecting it from contamination.

SMAW is a versatile welding process that can be used to weld a wide variety of metals, including steel, stainless steel, and aluminum. It is a relatively simple process to learn, and it can be used to create both high-quality and low-quality welds.

Equipment Used in SMAW

The equipment used in SMAW includes a welding machine, a welding cable, an electrode holder, and a variety of electrodes.

- The welding machine is the power source for the welding process. It provides the electrical current that creates the arc.

- The welding cable connects the welding machine to the electrode holder.

- The electrode holder is used to hold the electrode in place.

- The electrodes are consumable rods that are made of a metal that is compatible with the metal being welded.

Materials That Can Be Welded Using SMAW

SMAW can be used to weld a wide variety of metals, including:

- Steel

- Stainless steel

- Aluminum

- Cast iron

- Copper

- Nickel

SMAW Welding Techniques: Smaw Is Often Referred To As

SMAW employs several distinct welding techniques, each tailored to specific applications. Understanding these techniques is crucial for achieving optimal welding results.

Weaving Technique

In the weaving technique, the electrode is moved back and forth across the weld joint, creating a series of overlapping beads. This technique provides a wider weld bead, resulting in increased weld strength and penetration. However, it requires more skill and practice to master.

Stringer Bead Technique

The stringer bead technique involves holding the electrode steady and moving it forward along the weld joint, creating a single, continuous bead. This technique is simpler to execute and is suitable for thinner materials. However, it produces a narrower weld bead with less penetration compared to the weaving technique.

Backstep Technique

The backstep technique is a variation of the stringer bead technique, where the electrode is moved forward and then slightly back before continuing forward. This technique helps to fill in gaps and ensure complete fusion of the weld joint. It is particularly useful for thicker materials and situations where deep penetration is required.

Tips for Improving SMAW Welding Techniques

- Practice regularly to develop coordination and muscle memory.

- Choose the appropriate electrode size and type for the specific application.

- Maintain a consistent arc length to ensure proper penetration and bead formation.

- Use proper shielding gas to prevent oxidation and contamination of the weld.

- Clean the weld joint thoroughly before welding to remove any impurities.

SMAW Applications

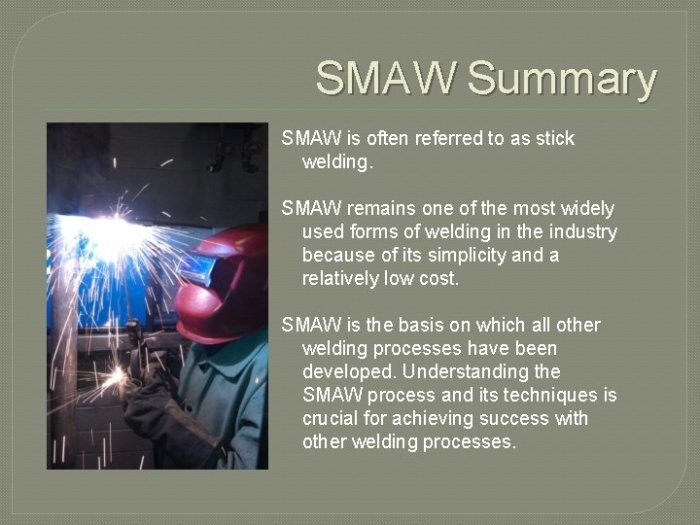

Shielded Metal Arc Welding (SMAW), often referred to as stick welding, is widely used in various industries due to its versatility, affordability, and ease of use. Here are some of the industries where SMAW is commonly employed:

Construction, Smaw is often referred to as

SMAW is a popular choice in construction for welding structural steel components, pipelines, and pressure vessels. It is particularly useful for outdoor applications where portability and durability are essential.

Shipbuilding

SMAW is extensively used in shipbuilding for welding steel hulls, decks, and other structural components. It is preferred due to its ability to produce strong and reliable welds in challenging environments.

SMAW is often referred to as arc welding, a process that uses an electric arc to melt and join metals. Incidentally, did you know about the nims is 800 test answers ? Anyway, back to SMAW: it is a versatile welding technique that can be used for a wide range of applications.

Automotive

SMAW is used in the automotive industry for welding chassis, exhaust systems, and other metal components. It is particularly suitable for repairing and maintaining vehicles.

Aerospace

SMAW is employed in the aerospace industry for welding aircraft components, such as landing gear, engine mounts, and fuselage frames. It is valued for its ability to produce high-quality welds with precise control.

Advantages of SMAW

The advantages of using SMAW in these industries include:

- Versatility:SMAW can be used to weld a wide range of metals, including steel, stainless steel, cast iron, and aluminum.

- Portability:SMAW equipment is relatively lightweight and portable, making it ideal for outdoor and on-site applications.

- Affordability:SMAW is generally more affordable than other welding processes, making it a cost-effective option.

- Ease of use:SMAW is relatively easy to learn and operate, making it accessible to welders of all skill levels.

Safety Considerations in SMAW

SMAW, like any welding process, involves potential hazards that must be addressed to ensure a safe working environment. These hazards include:

- Electric shock

- Arc flash and burns

- Fumes and gases

- Fire and explosion

To mitigate these hazards, it is essential to implement safety precautions, including:

- Wearing appropriate personal protective equipment (PPE), such as welding helmet, gloves, and flame-resistant clothing

- Ensuring proper ventilation to remove fumes and gases

- Maintaining a clean and organized work area

- Inspecting equipment regularly and ensuring it is in good working order

Importance of Proper Training and Certification

Proper training and certification are crucial for SMAW operators. These programs provide comprehensive knowledge of the process, safety procedures, and best practices. Certified operators demonstrate proficiency in operating SMAW equipment, understanding the hazards involved, and implementing appropriate safety measures.

Query Resolution

What are the advantages of using SMAW?

SMAW offers several advantages, including its versatility in welding various metals, its portability, and its ability to produce high-quality welds in both indoor and outdoor environments.

What are the safety precautions that should be taken when using SMAW?

When using SMAW, it is essential to wear appropriate protective gear, including a welding helmet, gloves, and flame-resistant clothing. Proper ventilation is also crucial to prevent exposure to welding fumes.

What are some common applications of SMAW?

SMAW is widely used in industries such as construction, shipbuilding, automotive repair, and manufacturing. It is particularly suitable for welding thick metals and for applications where portability is required.