Run and start capacitors are interchangeable in certain situations – In the realm of electrical engineering, run and start capacitors play crucial roles in the operation of motors. While distinct in their functions, these capacitors may be interchangeable in certain situations. This article delves into the intricacies of this interchangeability, exploring the technical considerations, risks, and best practices involved.

Run capacitors maintain motor operation at a steady speed, while start capacitors provide the initial boost of torque to overcome inertia. Understanding the key differences between these capacitors is essential for determining their suitability for interchangeable use.

Interchangeability of Run and Start Capacitors

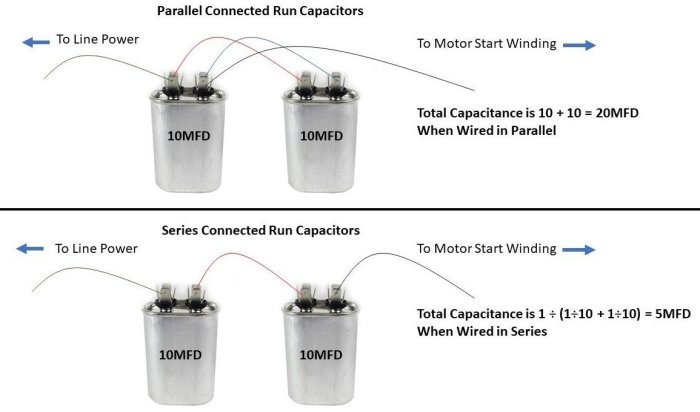

Run and start capacitors are both essential components in electric motors, serving distinct yet complementary functions. Run capacitors maintain motor operation at a constant speed, while start capacitors provide an initial boost to overcome the starting torque required to initiate motor rotation.

Interchangeability Situations

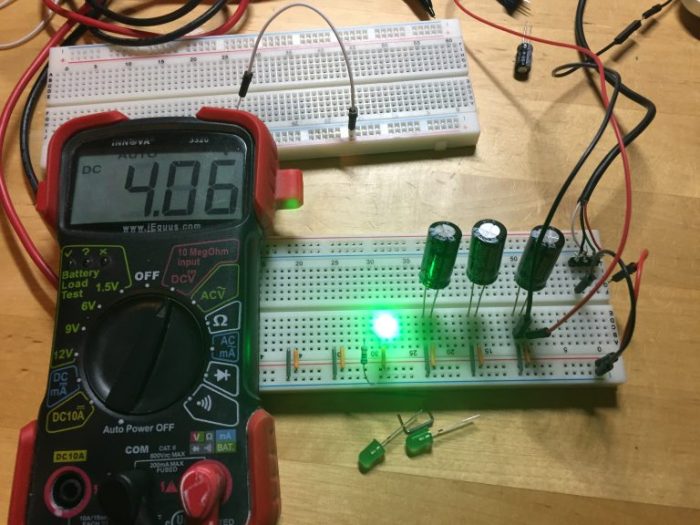

In certain situations, run and start capacitors can be used interchangeably. This is typically possible when the following conditions are met:

- Similar capacitance values

- Equivalent voltage ratings

- Compatible physical dimensions

Technical Considerations

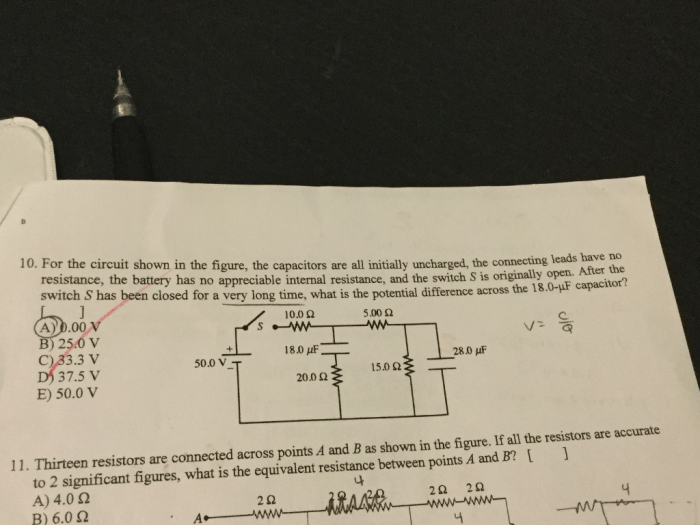

When considering interchangeability, it is crucial to examine the technical specifications of both capacitors. The capacitance value, voltage rating, and physical dimensions must be carefully compared to ensure proper functionality and safety.

Capacitance: The capacitance value determines the amount of electrical charge the capacitor can store. Interchanging capacitors with different capacitance values may result in motor performance issues.

Voltage Rating: The voltage rating indicates the maximum voltage the capacitor can withstand without failure. Using a capacitor with a lower voltage rating than required can lead to premature failure.

Physical Dimensions: The physical dimensions of the capacitor, including its size and shape, must match the motor’s design to ensure proper fit and operation.

Risks and Consequences, Run and start capacitors are interchangeable in certain situations

Using run and start capacitors interchangeably without proper consideration can lead to various risks and consequences:

- Reduced motor performance

- Increased energy consumption

- Shortened motor lifespan

Best Practices

To ensure safe and reliable operation, it is essential to follow best practices when using run and start capacitors:

- Use capacitors that meet industry standards and specifications.

- Match the capacitance value, voltage rating, and physical dimensions to the motor’s requirements.

- Install and maintain capacitors according to manufacturer’s instructions.

- Replace capacitors when they fail or show signs of deterioration.

Expert Answers: Run And Start Capacitors Are Interchangeable In Certain Situations

Can run and start capacitors always be used interchangeably?

No, interchangeability is limited to specific situations and depends on factors such as capacitance, voltage rating, and motor characteristics.

What are the risks of using run and start capacitors interchangeably?

Potential risks include reduced motor performance, decreased efficiency, and shortened lifespan.

How can I determine if run and start capacitors are interchangeable in my application?

Consult the motor manufacturer’s specifications or seek guidance from a qualified electrician.